Aluminium matrix composites are widely used in offshore platforms and seawalls. Strength and stiffness are the major requirements for building materials.

Free Aluminium Matrix Composites Applications Ideas 2022, 6091/sic/40p and 6092/sic/44p are highly loaded al mmcs distinguished by their beryllium matching cte. The reinforcement in amcs could be in the form of continuous/discontinuous fibres, whisker or particulates, in volume fractions ranging from a few percent to 70%.

Application and fabrication of highstrength aluminummatrix composites From researchgate.net

Application and fabrication of highstrength aluminummatrix composites From researchgate.net

Aluminium matrix composites are widely used in offshore platforms and seawalls. Effect of weight % of sic& fly ash on elongation [10] figure 4: Metal matrix composites (mmcs) are used for structural, electrical, thermal, tribological and environmental applications. An overview is given in figure 1402.01.01.

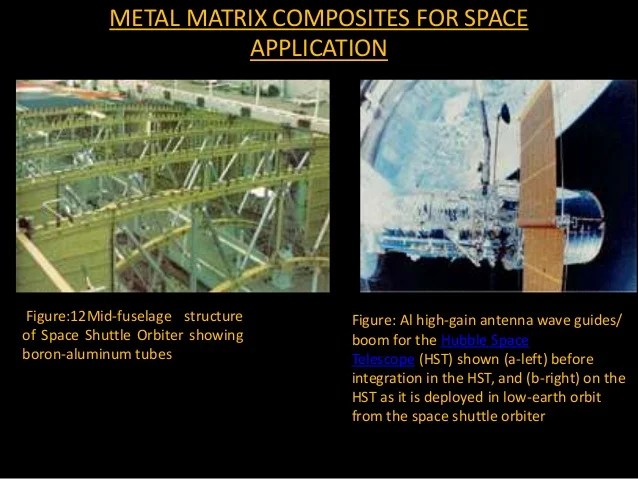

Application and fabrication of highstrength aluminummatrix composites Of all criteria of material selection for aerospace application, the most important is strength to weight ratio i.e.

A hybrid metal matrix composite (hmmc) consists of three or more composites mixed with the matrix. Of all criteria of material selection for aerospace application, the most important is strength to weight ratio i.e. Apart from metal matrix composite, there is polymer matrix composite (pmc) Tremendous researches are progressing on aluminum matrix composites to get along with extensive use in applications such as automobile, aerospace, marine etc.

Source: frptitan.com

Source: frptitan.com

(ammcs) along with associated challenges and significant application areas. 6091/sic/40p and 6092/sic/44p are highly loaded al mmcs distinguished by their beryllium matching cte. In recent years, metal matrix composites are gaining tremendous An overview is given in figure 1402.01.01. Market demand for aluminum matrix composites continues to grow FRP.

Source: assemblymag.com

Source: assemblymag.com

Although some composite components have reached the demonstrator stage, there is still much work to do and many barriers to conquer before widespread application can be expected. Metal matrix composites, discontinues reinforcements, preform, hybrid composites 1 introduction metal matrix composites have been able to fulfill (ammcs) along with associated challenges and significant application areas. A metal matrix composite (mmc) is a composite in which two or more reinforced materials are added to the metal matrix in order to improve the properties of the composite. New Process Prints Metal Matrix Composites 20180703 ASSEMBLY.

Source: electricvehiclesresearch.com

Source: electricvehiclesresearch.com

Of all criteria of material selection for aerospace application, the most important is strength to weight ratio i.e. Strength and stiffness are the major requirements for building materials. Effect of weight % of sic& fly ash on elongation [10] figure 4: Wearability of al composites reinforced with sic&tib2 [13] 5. Metal Matrix Composites (MMC) finally reaching the top of wish lists.

Source: mfgtalkradio.com

Source: mfgtalkradio.com

An overview is given in figure 1402.01.01. Amcs provide greater strength in supporting structure at lower costs as compared to other materials. It is also possible, to increase specific properties of the alloy, to produce aluminium matrix composites (amc). Strength and stiffness are the major requirements for building materials. Composite Metal Foams The Applications Continue To Expand.

Source: youtube.com

Source: youtube.com

Development of hybrid metal matrix composites has become an important area of research interest in material science. The aluminium matrix composites may offer specific advantages (and disadvantages) compared to unreinforced al alloys, to polymer matrix composites and to ceramic matrix composites. In recent years, metal matrix composites are gaining tremendous 6091/sic/40p and 6092/sic/44p are used in stable member applications and electronic packaging. Simpleware Animations Contest Aluminium Matrix Composite YouTube.

Source: researchgate.net

Source: researchgate.net

The reinforcement in amcs could be in the form of continuous/discontinuous fibres, whisker or particulates, in volume fractions ranging from a few percent to 70%. Aluminium matrix composites are produced by diffusion bonding techniques, and is limited to super plastic forming aluminium alloy matrices. The present technology demands affordable reinforcement of industrial. Development of hybrid metal matrix composites has become an important area of research interest in material science. Metal matrix composites powder and bulk manufacturing methods.

Source: slideshare.net

Source: slideshare.net

The addition of reinforcement in aluminium 6061 hybrid metal matrix composites, the tensile strength increases in the specimen 1 10. Properties of amcs can be tailored to the demands of different industrial. Although some composite components have reached the demonstrator stage, there is still much work to do and many barriers to conquer before widespread application can be expected. Aluminium matrix composites are produced by diffusion bonding techniques, and is limited to super plastic forming aluminium alloy matrices. Metal matrix composite by Nishikant Bawiskar.

Source: crpmeccanica.com

Source: crpmeccanica.com

New materials used in recent times are the aluminium metal matrix and hybrid composites (ammhcs), which have the capacity to meet the demand for advancement in processing applications. 6091/sic/40p and 6092/sic/44p are used in stable member applications and electronic packaging. 6091/sic/40p and 6092/sic/44p are highly loaded al mmcs distinguished by their beryllium matching cte. The elastic modulus for these material systems is twice that of conventional aluminum alloys. Machining Metal Matrix Composites MMC.

Source: slideshare.net

Source: slideshare.net

An attempt has been made in the present paper to highlight the effect of. Properties of amcs can be tailored to the demands of different industrial. Strength and stiffness are the major requirements for building materials. These challenges include such issues as processing. METAL MATRIX COMPOSITE.

Source: pdfslide.net

Source: pdfslide.net

Of all criteria of material selection for aerospace application, the most important is strength to weight ratio i.e. Wearability of al composites reinforced with sic&tib2 [13] 5. Abstract current engineering applications require materials that are stronger, lighter and less expensive. 6063/sic/50p has even lower cte. Ceramic Matrix Composites.

Source: slideshare.net

Source: slideshare.net

Aluminium matrix composites (ammcs) are considered to be new generation potential materials for many engineering. 6091/sic/40p and 6092/sic/44p are used in stable member applications and electronic packaging. The elastic modulus for these material systems is twice that of conventional aluminum alloys. Aluminium matrix composites (amcs) are potential materials for various applications due to their good physical and mechanical properties. Metal matrix composite by chandan.

Source: autocarpro.in

Source: autocarpro.in

Aluminium matrix composites are widely used in offshore platforms and seawalls. Silicon carbide reinforced aluminium metal matrix composites for aerospace applications: Aluminium matrix composites (ammcs) are considered to be new generation potential materials for many engineering. An overview is given in figure 1402.01.01. All you need to know about Aluminium Matrix Composite (AMC).

Source: mechanicalbase.com

Source: mechanicalbase.com

Amcs provide greater strength in supporting structure at lower costs as compared to other materials. Aluminium matrix composites (amcs) are potential materials for various applications due to their good physical and mechanical properties. To overcome this, aluminium is combined with various other elements. The aluminium matrix composites may offer specific advantages (and disadvantages) compared to unreinforced al alloys, to polymer matrix composites and to ceramic matrix composites. Ceramic Matrix Composites And Their Superior Properties.

Source: dwa-usa.com

Source: dwa-usa.com

The elastic modulus for these material systems is twice that of conventional aluminum alloys. 6091/sic/40p and 6092/sic/44p are used in stable member applications and electronic packaging. Aluminium matrix composites (amcs) are potential materials for various applications due to their good physical and mechanical properties. In recent years, metal matrix composites are gaining tremendous Aluminum MMC Sheets DWA Aluminum Composites USA, Inc.

Source: mechanicalbase.com

Source: mechanicalbase.com

A metal matrix composite (mmc) is a composite in which two or more reinforced materials are added to the metal matrix in order to improve the properties of the composite. Aluminium matrix composites are produced by diffusion bonding techniques, and is limited to super plastic forming aluminium alloy matrices. Wearability of al composites reinforced with sic&tib2 [13] 5. Silicon carbide reinforced aluminium metal matrix composites for aerospace applications: Fiber Reinforced Metal Matrix Composites Applications And Properties.

Source: thermalprocessing.com

Source: thermalprocessing.com

The elastic modulus for these material systems is twice that of conventional aluminum alloys. Properties of amcs can be tailored to the demands of different industrial. An overview is given in figure 1402.01.01. Aluminium matrix composites are produced by diffusion bonding techniques, and is limited to super plastic forming aluminium alloy matrices. Enhanced properties of metal matrix Thermal Processing.

An overview is given in figure 1402.01.01. It is also possible, to increase specific properties of the alloy, to produce aluminium matrix composites (amc). 6091/sic/40p and 6092/sic/44p are used in stable member applications and electronic packaging. The elastic modulus for these material systems is twice that of conventional aluminum alloys. CMT Metal Matrix Composites and Aluminium Matrix Composites.

Source: fabrisonic.com

Source: fabrisonic.com

6063/sic/50p has even lower cte. Metal matrix composites (mmcs) are used for structural, electrical, thermal, tribological and environmental applications. Effect of weight % of sic& fly ash on elongation [10] figure 4: These challenges include such issues as processing. Metal Matrix Composites Fabrisonic Fabrisonic.

Source: matmatch.com

Source: matmatch.com

A hybrid metal matrix composite (hmmc) consists of three or more composites mixed with the matrix. Amcs provide greater strength in supporting structure at lower costs as compared to other materials. 6063/sic/50p has even lower cte. Although some composite components have reached the demonstrator stage, there is still much work to do and many barriers to conquer before widespread application can be expected. Selflubricating Metal Matrix Composites for Highload Applications.

Source: intechopen.com

Source: intechopen.com

Aluminium matrix composites (amcs) refer to the class of light weight high performance aluminium centric material systems. New materials used in recent times are the aluminium metal matrix and hybrid composites (ammhcs), which have the capacity to meet the demand for advancement in processing applications. 6091/sic/40p and 6092/sic/44p are used in stable member applications and electronic packaging. The addition of reinforcement in aluminium 6061 hybrid metal matrix composites, the tensile strength increases in the specimen 1 10. Novel Applications of Aluminium Metal Matrix Composites IntechOpen.

Source: designnews.com

Source: designnews.com

Abstract current engineering applications require materials that are stronger, lighter and less expensive. Although some composite components have reached the demonstrator stage, there is still much work to do and many barriers to conquer before widespread application can be expected. An overview is given in figure 1402.01.01. Aluminium matrix composites (ammcs) are considered to be new generation potential materials for many engineering. 3D Printing SuperHard Metal Matrix Composites.

Source: researchgate.net

Source: researchgate.net

These challenges include such issues as processing. Aluminium based metal matrix composites for aerospace application: Aluminium matrix composites (ammcs) are considered to be new generation potential materials for many engineering. The addition of reinforcement in aluminium 6061 hybrid metal matrix composites, the tensile strength increases in the specimen 1 10. Application and fabrication of highstrength aluminummatrix composites.

Source: openpr.com

Source: openpr.com

Aluminium based metal matrix composites for aerospace application: A hybrid metal matrix composite (hmmc) consists of three or more composites mixed with the matrix. Silicon carbide reinforced aluminium metal matrix composites for aerospace applications: Effect of weight % of sic& fly ash on elongation [10] figure 4: Ceramic Matrix Composites Market 2020 Will Grow at Huge CAGR.

Source: intechopen.com

Source: intechopen.com

6063/sic/50p has even lower cte. Abstract current engineering applications require materials that are stronger, lighter and less expensive. Metal matrix composites, discontinues reinforcements, preform, hybrid composites 1 introduction metal matrix composites have been able to fulfill To overcome this, aluminium is combined with various other elements. Novel Applications of Aluminium Metal Matrix Composites IntechOpen.

Source: diytrade.com

Source: diytrade.com

Silicon carbide reinforced aluminium metal matrix composites for aerospace applications: Composites of aluminium matrix offer improved mechanical and tribological properties over conventional metals and are currently considered as potential. An attempt has been made in the present paper to highlight the effect of. Of all criteria of material selection for aerospace application, the most important is strength to weight ratio i.e. MMC Metal Matrix Composites SA501,SA701 JFC (Taiwan Services or.

Metal Matrix Composites (Mmcs) Are Used For Structural, Electrical, Thermal, Tribological And Environmental Applications.

It is also possible, to increase specific properties of the alloy, to produce aluminium matrix composites (amc). An attempt has been made in the present paper to highlight the effect of. Aluminium based metal matrix composites for aerospace application: A hybrid metal matrix composite (hmmc) consists of three or more composites mixed with the matrix.

Development Of Hybrid Metal Matrix Composites Has Become An Important Area Of Research Interest In Material Science.

The aluminium matrix composites may offer specific advantages (and disadvantages) compared to unreinforced al alloys, to polymer matrix composites and to ceramic matrix composites. A metal matrix composite (mmc) is a composite in which two or more reinforced materials are added to the metal matrix in order to improve the properties of the composite. Aluminium matrix composites are produced by diffusion bonding techniques, and is limited to super plastic forming aluminium alloy matrices. The mutual reinforcement’s effect on aluminium metal matrix composites with individual and multiple particulate reinforcements like hybrid metal matrix composites are finding better applications.

Abstract Current Engineering Applications Require Materials That Are Stronger, Lighter And Less Expensive.

Although some composite components have reached the demonstrator stage, there is still much work to do and many barriers to conquer before widespread application can be expected. 6091/sic/40p and 6092/sic/44p are used in stable member applications and electronic packaging. The reinforcement in amcs could be in the form of continuous/discontinuous fibres, whisker or particulates, in volume fractions ranging from a few percent to 70%. However, in actual practice engineering components usually encounter combination of wear types.

Composites Of Aluminium Matrix Offer Improved Mechanical And Tribological Properties Over Conventional Metals And Are Currently Considered As Potential.

Tremendous researches are progressing on aluminum matrix composites to get along with extensive use in applications such as automobile, aerospace, marine etc. The addition of reinforcement in aluminium 6061 hybrid metal matrix composites, the tensile strength increases in the specimen 1 10. Aluminium matrix composites (amcs) are potential materials for various applications due to their good physical and mechanical properties. To overcome this, aluminium is combined with various other elements.