Property data given in this chapter are therefore Different cnt aspect ratios exhibited distinct mechanical properties with an ultimate.

Incredible Mechanical Properties Of Metal Matrix Composites With Creative Design, Some composites are built to have higher creep resistance than the pure metal counterparts. In particular copper/tungsten, copper/tungsten carbide.

Patent WO2005068176A1 High impact strength, elastic, composite, fibre From google.com.au

Patent WO2005068176A1 High impact strength, elastic, composite, fibre From google.com.au

Metal based composite materials, known as metal matrix composites (mmcs), are one of the major innovations in materials science and engineering since the late 19th century. This chapter describes the mechanical performance of a fibre composite. Shows the rout of metal matrix composite production it evaluates the mechanical properties of al7075. Also these materials are very good thermal and electrical conductors.

Patent WO2005068176A1 High impact strength, elastic, composite, fibre This paper presents mechanical and material properties of conducting alloys fabricated as functionally graded metal matrix composites (mmcs);

A review on the role of green reinforcements and processing methods february 2022 doi: In particular copper/tungsten, copper/tungsten carbide. This chapter describes the mechanical performance of a fibre composite. This paper presents mechanical and material properties of conducting alloys fabricated as functionally graded metal matrix composites (mmcs);

Source: researchgate.net

Source: researchgate.net

In this study, the scratch resistance of two different copper powders, dendritic and spherical, and their composites with traditional mos2, nanometric mos2, and graphene nanoplatelets was. All belong to the concept of “mechanical properties”. When the fibers are increased inside metal matrix, these mechanical properties are also increased. 2 1 as used i n this chapter, the terms1‘al u m inu m, ‘‘magnesium, ” and “titanium” denote alloysof these materials used as matrix metals. (PDF) A review on mechanical properties and wear behaviour of aluminium.

Source: researchgate.net

Source: researchgate.net

This article summarizes the mechanical and thermal properties of discontinuously reinforced aluminum mmcs, laminated metallic composites, and continuously aligned fiber reinforced mmcs. A review on the role of green reinforcements and processing methods february 2022 doi: Metal matrix composites (mmcs) are used for structural, electrical, thermal, tribological and environmental applications. Property data given in this chapter are therefore (PDF) Analysis of Mechanical Properties of Aluminium based Metal Matrix.

Source: scientific.net

Source: scientific.net

Metal matrix composites (mmcs) are used for structural, electrical, thermal, tribological and environmental applications. In particular copper/tungsten, copper/tungsten carbide. Property data given in this chapter are therefore This article summarizes the mechanical and thermal properties of discontinuously reinforced aluminum mmcs, laminated metallic composites, and continuously aligned fiber reinforced mmcs. Effect of Weight Percentage on Mechanical Properties of Boron Carbide.

Source: researchgate.net

Source: researchgate.net

Introduction topics such as elastic properties of materials, fracture toughness, fatigue crack propagation, plastic yielding at room temperature, at elevated temperatures, creep, viscous flow etc. This chapter describes the mechanical performance of a fibre composite. Metal matrix composites are generally fabricated by liquid metallurgy route. Bowen (university of birmingham, uk) received 17 june 1992; (PDF) Production and mechanical properties of AlSiC metal matrix.

Source: researchgate.net

Source: researchgate.net

Also these materials are very good thermal and electrical conductors. Physical and mechanical properties of target plates and projectiles used in this. Are replacing conventional metallic materials in automobile and aerospace industries. Innovative nanostructured materials offer the possibility of enhancing the tribological performance of traditional materials like graphite and molybdenum disulfide (mos2). (PDF) An overview on mechanical properties of particulate reinforced.

Source: degruyter.com

Source: degruyter.com

All belong to the concept of “mechanical properties”. Property data given in this chapter are therefore Stir casting process is termed as liquid metallurgy route which is employed for fabrication of metal Aluminum based hybrid metal matrix composite have found extensive applications in field of automobiles. Research review of diversified reinforcement on aluminum metal matrix.

Source: slideserve.com

Source: slideserve.com

Introduction topics such as elastic properties of materials, fracture toughness, fatigue crack propagation, plastic yielding at room temperature, at elevated temperatures, creep, viscous flow etc. Are replacing conventional metallic materials in automobile and aerospace industries. The axial moduli of these composites are much greater than those of the monolithic metals. Bowen (university of birmingham, uk) received 17 june 1992; PPT Mechanical Properties of Metals PowerPoint Presentation, free.

Source: researchgate.net

Source: researchgate.net

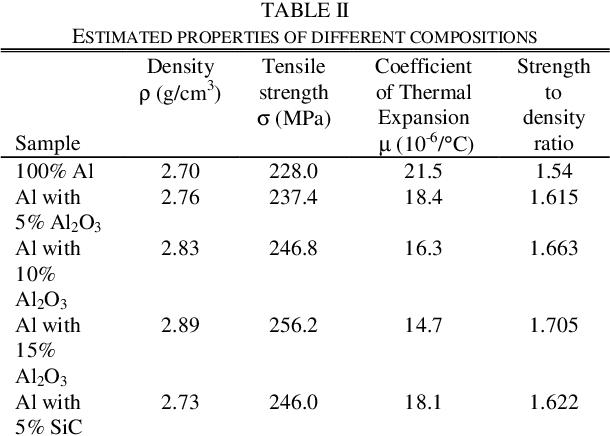

Property data given in this chapter are therefore Properties of metal matrix composites. The mechanical characteristics include wear resistance, tensile strength, and flexural strength to inflict different experimental researches. And the role of the matrix. Mechanical properties of different composite materials. Download Table.

Source: researchgate.net

Source: researchgate.net

Different cnt aspect ratios exhibited distinct mechanical properties with an ultimate. This chapter describes the mechanical performance of a fibre composite. All belong to the concept of “mechanical properties”. Property data given in this chapter are therefore (PDF) Investigations for Mechanical Properties of Metal Matrix.

Source: researchgate.net

Source: researchgate.net

This article summarizes the mechanical and thermal properties of discontinuously reinforced aluminum mmcs, laminated metallic composites, and continuously aligned fiber reinforced mmcs. Innovative nanostructured materials offer the possibility of enhancing the tribological performance of traditional materials like graphite and molybdenum disulfide (mos2). High specific mechanical properties while nickel mmcs provide the ability the retain excellent mechanical strength, resist oxidation, and reduce thermal creep at extreme. In this study, the scratch resistance of two different copper powders, dendritic and spherical, and their composites with traditional mos2, nanometric mos2, and graphene nanoplatelets was. (PDF) Mechanical properties of leaf ashes reinforced aluminum alloy.

Source: researchgate.net

Source: researchgate.net

According to the application, the alignment of fiber reinforcements are adjusted. Mechanical properties of sustainable metal matrix composites: Also these materials are very good thermal and electrical conductors. A review on the role of green reinforcements and processing methods february 2022 doi: (PDF) Material characterisation and mechanical properties of Al2O3Al.

Source: pdfslide.net

Source: pdfslide.net

A review on the role of green reinforcements and processing methods february 2022 doi: Even though, various kinds of mmcs have been developed over the years, among them, aluminum (al) and magnesium (mg) mmcs. Some composites are built to have higher creep resistance than the pure metal counterparts. Aluminum based hybrid metal matrix composite have found extensive applications in field of automobiles. Fabrication and Analysis of Mechanical Properties of Metal Matrix Nano.

Source: researchgate.net

Source: researchgate.net

Metal matrix composites (mmcs) are used for structural, electrical, thermal, tribological and environmental applications. This article summarizes the mechanical and thermal properties of discontinuously reinforced aluminum mmcs, laminated metallic composites, and continuously aligned fiber reinforced mmcs. Innovative nanostructured materials offer the possibility of enhancing the tribological performance of traditional materials like graphite and molybdenum disulfide (mos2). In particular copper/tungsten, copper/tungsten carbide. (PDF) Effect of Reinforcement Particle Size and Weight Fraction on the.

Source: what-when-how.com

Source: what-when-how.com

And the role of the matrix. This reduces the risk of warping or deformation in the material. Are replacing conventional metallic materials in automobile and aerospace industries. This paper presents mechanical and material properties of conducting alloys fabricated as functionally graded metal matrix composites (mmcs); Metalmatrix composites.

Source: slideshare.net

Source: slideshare.net

This is evident when exposed to tension or compression, as most metal matrix composites have high mechanical strength. In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement: In this study, the scratch resistance of two different copper powders, dendritic and spherical, and their composites with traditional mos2, nanometric mos2, and graphene nanoplatelets was. Mechanical properties of metals and composites 5.7.1. METAL MATRIX COMPOSITE.

Source: google.com.au

Source: google.com.au

All belong to the concept of “mechanical properties”. Mechanical properties of metals and composites 5.7.1. Aluminum based hybrid metal matrix composite have found extensive applications in field of automobiles. Introduction topics such as elastic properties of materials, fracture toughness, fatigue crack propagation, plastic yielding at room temperature, at elevated temperatures, creep, viscous flow etc. Patent WO2005068176A1 High impact strength, elastic, composite, fibre.

Source: researchgate.net

Source: researchgate.net

Different cnt aspect ratios exhibited distinct mechanical properties with an ultimate. The axial moduli of these composites are much greater than those of the monolithic metals. Bowen (university of birmingham, uk) received 17 june 1992; Even though, various kinds of mmcs have been developed over the years, among them, aluminum (al) and magnesium (mg) mmcs. (PDF) Investigation of Mechanical Properties of Aluminium Based Metal.

Source: slideserve.com

Source: slideserve.com

Stir casting process is termed as liquid metallurgy route which is employed for fabrication of metal In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement: Kumar gb, rao csp, selvaraj n, bhagyashekar ms. Property data given in this chapter are therefore PPT Metal Matrix Composites PowerPoint Presentation ID4344148.

Source: semanticscholar.org

Source: semanticscholar.org

Mechanical properties of metals and composites 5.7.1. A review on the role of green reinforcements and processing methods february 2022 doi: Aluminum based hybrid metal matrix composite have found extensive applications in field of automobiles. High specific mechanical properties while nickel mmcs provide the ability the retain excellent mechanical strength, resist oxidation, and reduce thermal creep at extreme. Table II from Physiomechanical Properties of Aluminium Metal Matrix.

Source: researchgate.net

Source: researchgate.net

Mmc, metallurgy, stir casting, matrix, and reinforcement introduction a metal matrix composite contains a metal or an alloy because the continual matrix and reinforcement which can be This paper presents mechanical and material properties of conducting alloys fabricated as functionally graded metal matrix composites (mmcs); This reduces the risk of warping or deformation in the material. Jor source of differences in reported properties. (PDF) Enhanced Mechanical Properties of Al6061 Metal Matrix Composites.

Source: researchgate.net

Source: researchgate.net

Kumar gb, rao csp, selvaraj n, bhagyashekar ms. In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement: Mechanical properties of sustainable metal matrix composites: This chapter describes the mechanical performance of a fibre composite. (PDF) Analysis of Dynamic Behaviour and Mechanical Properties of.

Source: researchgate.net

Source: researchgate.net

Mechanical properties of sustainable metal matrix composites: Also these materials are very good thermal and electrical conductors. 2 1 as used i n this chapter, the terms1‘al u m inu m, ‘‘magnesium, ” and “titanium” denote alloysof these materials used as matrix metals. Physical and mechanical properties of target plates and projectiles used in this. (PDF) Performance of Mechanical Properties of Hybrid Aluminium Based.

Source: researchgate.net

Source: researchgate.net

The mechanical characteristics include wear resistance, tensile strength, and flexural strength to inflict different experimental researches. 2 1 as used i n this chapter, the terms1‘al u m inu m, ‘‘magnesium, ” and “titanium” denote alloysof these materials used as matrix metals. Aluminum based hybrid metal matrix composite have found extensive applications in field of automobiles. A review on the role of green reinforcements and processing methods february 2022 doi: (PDF) Enhancing the Mechanical Properties of Metal Matrix Composite by.

Source: researchgate.net

Source: researchgate.net

Development of hybrid metal matrix composites has become an important area of research interest in material science. Properties of metal matrix composites. This paper presents mechanical and material properties of conducting alloys fabricated as functionally graded metal matrix composites (mmcs); Different cnt aspect ratios exhibited distinct mechanical properties with an ultimate. Mechanical properties of the composite material Download Scientific.

Source: mdpi.com

Source: mdpi.com

In particular copper/tungsten, copper/tungsten carbide. According to the application, the alignment of fiber reinforcements are adjusted. Taguchi techniques were applied to examine the mechanical property of sic and al6063 reinforced metal matrix composites. This article summarizes the mechanical and thermal properties of discontinuously reinforced aluminum mmcs, laminated metallic composites, and continuously aligned fiber reinforced mmcs. Materials Free FullText Improved Mechanical and Tribological.

And The Role Of The Matrix.

Even though, various kinds of mmcs have been developed over the years, among them, aluminum (al) and magnesium (mg) mmcs. Some composites are built to have higher creep resistance than the pure metal counterparts. In the lmr process before solidification, the particles are dispersed. Mechanical properties of metals and composites 5.7.1.

High Specific Mechanical Properties While Nickel Mmcs Provide The Ability The Retain Excellent Mechanical Strength, Resist Oxidation, And Reduce Thermal Creep At Extreme.

Different cnt aspect ratios exhibited distinct mechanical properties with an ultimate. In this study, the scratch resistance of two different copper powders, dendritic and spherical, and their composites with traditional mos2, nanometric mos2, and graphene nanoplatelets was. Taguchi techniques were applied to examine the mechanical property of sic and al6063 reinforced metal matrix composites. Metal matrix composites (mmcs) because of their excellent properties such as light weight, higher ductility, higher strength etc.

The Mechanical Characteristics Include Wear Resistance, Tensile Strength, And Flexural Strength To Inflict Different Experimental Researches.

Properties of metal matrix composites. Kumar gb, rao csp, selvaraj n, bhagyashekar ms. This is evident when exposed to tension or compression, as most metal matrix composites have high mechanical strength. ~carl zweben, “metal matrix composites, ” contractor report for ota, january 1987.

Bowen (University Of Birmingham, Uk) Received 17 June 1992;

Stir casting process is termed as liquid metallurgy route which is employed for fabrication of metal Metal matrix composites are generally fabricated by liquid metallurgy route. Property data given in this chapter are therefore Physical and mechanical properties of target plates and projectiles used in this.