For instance, defense, space application and automobile industries (bindumadhavan et al., 2001;prasad. For instance, welding electrode materials and electrical contact materials consist of a conductive matrix alloy of copper or silver with a tungsten, tungsten carbide, or cadmium oxide second phase, or reinforcement.

List Of Metal Matrix Composites Applications With New Ideas, In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement: These innovative materials open up unlimited possibilities for modern material science and development;

PPT Metal Matrix Composites (MMC) PowerPoint Presentation, free From slideserve.com

PPT Metal Matrix Composites (MMC) PowerPoint Presentation, free From slideserve.com

According to the application, the alignment of fiber reinforcements are adjusted. Aluminum metal matrix composites have properties that no other monolithic material can match. Metal matrix composites may have engineered properties for special applications. According to the application, the alignment of fiber reinforcements are adjusted.

PPT Metal Matrix Composites (MMC) PowerPoint Presentation, free Matrix composites synthesized by spark plasma sintering;

The applications of metal matrix composites (mmcs) are being increasing day by day in a number of industries, especially in aerospace and automobile industries. According to the application, the alignment of fiber reinforcements are adjusted. The combination of different materials can produce a unique and advantageous set of properties with the freedom to tailor the properties to specific application requirements by varying the fraction of reinforcement. Each chapter covers different perspectives of micro/nano reinforcement and related applications.

Source: researchgate.net

Source: researchgate.net

The nature of reinforcing, that can take the form of constant or undefined fibres, has a big influence on the. When the fibers are increased inside metal matrix, these mechanical properties are also increased. Metal matrix composites (mmcs) • a metal matrix composite (mmc) is composite material with at least two constituent parts, one being a metal. These innovative materials open up unlimited possibilities for modern material science and development; Microstructures of four kinds of metal matrix composites (a, b.

Source: kobo.com

Source: kobo.com

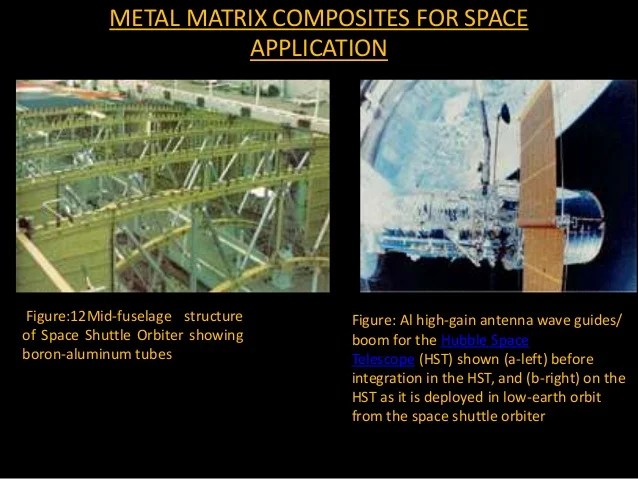

The metal matrix composites are deformed into different shapes, and the microstructure is changed to increase the strength of the composites. International journal of materials science and applications. The applications include ventral fin, fuel. This article provides information on the aerostructural, aeropropulsion, and aeronautical subsystem applications of mmcs. MetalMatrix Composites Innovations, Advances and Applications eBook by.

Source: researchgate.net

Source: researchgate.net

• the other material may be a different metal or another material, such as a ceramic or organic compound. The paper presents a brief state of the art of advanced ceramics, metal matrix and ceramic matrix composites. The metal matrix composites are deformed into different shapes, and the microstructure is changed to increase the strength of the composites. Each chapter covers different perspectives of micro/nano reinforcement and related applications. (PDF) Investigation on Mechanical, Tribological and Microstructural.

Source: researchgate.net

Source: researchgate.net

The damping capacity and slidingwear behavior of an aluminum; The plastic deformation can be categorized into traditional deformation and severe plastic deformation. Fabrication, structures, properties and applications (deadline: However, the main problem related to their processing is that controlling. 5. Types of metal matrix composites. (a) Continuous composite.

Source: electricvehiclesresearch.com

Source: electricvehiclesresearch.com

Metal matrix composites (mmcs) • a metal matrix composite (mmc) is composite material with at least two constituent parts, one being a metal. The characteristics of mmcs can be designed into the material. • example • when at least three materials are present, it is called a hybrid composite. Aluminum metal matrix composites have properties that no other monolithic material can match. Metal Matrix Composites (MMC) finally reaching the top of wish lists.

Source: matmatch.com

Source: matmatch.com

Metal matrix composites have a continuous metal matrix phase and one or more additional phases such as ceramic reinforcements. Each chapter covers different perspectives of micro/nano reinforcement and related applications. Metal matrix composites are the class of materials that have received great attention in the past decade owing to their superior specific properties and huge promise of application in various fields like aerospace, automotive, engineering, biomedical, and electronic applications. In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement: Selflubricating Metal Matrix Composites for Highload Applications.

Source: researchgate.net

Source: researchgate.net

These innovative materials open up unlimited possibilities for modern material science and development; For instance, defense, space application and automobile industries (bindumadhavan et al., 2001;prasad. The paper presents a brief state of the art of advanced ceramics, metal matrix and ceramic matrix composites. Numerous researches have been carried out on the developments of metal matrix composites (mmcs) in various applications. Metal matrix composites powder and bulk manufacturing methods.

Source: slideserve.com

Source: slideserve.com

This article provides information on the aerostructural, aeropropulsion, and aeronautical subsystem applications of mmcs. According to the application, the alignment of fiber reinforcements are adjusted. These innovative materials open up unlimited possibilities for modern material science and development; Aluminum based metal matrix composite (amcs) materials are preferred in numerous applications; PPT Metal Matrix Composites (MMC) PowerPoint Presentation, free.

Source: novapublishers.com

Source: novapublishers.com

Fabrication, structures, properties and applications (deadline: According to the application, the alignment of fiber reinforcements are adjusted. The metal matrix composites are deformed into different shapes, and the microstructure is changed to increase the strength of the composites. The damping capacity and slidingwear behavior of an aluminum; Engineered Metal Matrix Composites Forming Methods, Material.

Source: crpmeccanica.com

Source: crpmeccanica.com

The nature of reinforcing, that can take the form of constant or undefined fibres, has a big influence on the. Hunt jr., in comprehensive composite materials, 2000 6.05.2.1.4 other aerospace. Experimental testing and fabrication of metal matrix composite for automotive applications. • the other material may be a different metal or another material, such as a ceramic or organic compound. Machining Metal Matrix Composites MMC.

Source: slideshare.net

Source: slideshare.net

Metal matrix composites have a continuous metal matrix phase and one or more additional phases such as ceramic reinforcements. The metal matrix composites are deformed into different shapes, and the microstructure is changed to increase the strength of the composites. The applications include ventral fin, fuel. The plastic deformation can be categorized into traditional deformation and severe plastic deformation. Metal matrix composites.

Source: slideshare.net

Source: slideshare.net

Magnesium matrix composites for biomedical applications: The characteristics of mmcs can be designed into the material. In mmcs, the reinforcement usually takes the form of particles, whiskers, short fibers, or continuous fibers. Following special issues within this section are currently open for submissions: Metal matrix composite by Nishikant Bawiskar.

International journal of materials science and applications. The paper presents a brief state of the art of advanced ceramics, metal matrix and ceramic matrix composites. This article provides information on the aerostructural, aeropropulsion, and aeronautical subsystem applications of mmcs. The damping capacity and slidingwear behavior of an aluminum; CMT Metal Matrix Composites and Aluminium Matrix Composites.

Source: designnews.com

Source: designnews.com

Matrix composites synthesized by spark plasma sintering; The paper presents a brief state of the art of advanced ceramics, metal matrix and ceramic matrix composites. In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement: Each chapter covers different perspectives of micro/nano reinforcement and related applications. 3D Printing SuperHard Metal Matrix Composites.

Source: mdpi.com

Source: mdpi.com

Metal matrix composites may have engineered properties for special applications. The metal matrix composites are deformed into different shapes, and the microstructure is changed to increase the strength of the composites. The damping capacity and slidingwear behavior of an aluminum; When the fibers are increased inside metal matrix, these mechanical properties are also increased. Metals Free FullText Metallurgical Challenges in Carbon Nanotube.

Source: assemblymag.com

Source: assemblymag.com

Ceramic reinforced metal matrix nanocomposites (deadline: In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement: Due to their superior strength to conventional materials, aluminium matrix composites (amcs) have a broad variety of industrial applications. Also these materials are very good thermal and electrical conductors. New Process Prints Metal Matrix Composites 20180703 ASSEMBLY.

Source: diytrade.com

Source: diytrade.com

For instance, defense, space application and automobile industries (bindumadhavan et al., 2001;prasad. Following special issues within this section are currently open for submissions: Metal matrix composites (mmcs) • a metal matrix composite (mmc) is composite material with at least two constituent parts, one being a metal. However, the main problem related to their processing is that controlling. MMC Metal Matrix Composites SA501,SA701 JFC (Taiwan Services or.

Source: slideshare.net

Source: slideshare.net

Due to their superior strength to conventional materials, aluminium matrix composites (amcs) have a broad variety of industrial applications. Magnesium matrix composites for biomedical applications: Each chapter covers different perspectives of micro/nano reinforcement and related applications. The plastic deformation can be categorized into traditional deformation and severe plastic deformation. METAL MATRIX COMPOSITE.

Source: researchgate.net

Source: researchgate.net

These innovative materials open up unlimited possibilities for modern material science and development; Ceramic reinforced metal matrix nanocomposites (deadline: Hunt jr., in comprehensive composite materials, 2000 6.05.2.1.4 other aerospace. Due to their superior strength to conventional materials, aluminium matrix composites (amcs) have a broad variety of industrial applications. Application and fabrication of highstrength aluminummatrix composites.

Source: slideshare.net

Source: slideshare.net

Following special issues within this section are currently open for submissions: Aluminum metal matrix composites have properties that no other monolithic material can match. The plastic deformation can be categorized into traditional deformation and severe plastic deformation. Applications for metal matrix composites. Metal matrix composite by chandan.

Source: fabrisonic.com

Source: fabrisonic.com

The metal matrix composites are deformed into different shapes, and the microstructure is changed to increase the strength of the composites. Fabrication, structures, properties and applications (deadline: For instance, welding electrode materials and electrical contact materials consist of a conductive matrix alloy of copper or silver with a tungsten, tungsten carbide, or cadmium oxide second phase, or reinforcement. Due to their superior strength to conventional materials, aluminium matrix composites (amcs) have a broad variety of industrial applications. Metal Matrix Composites Fabrisonic Fabrisonic.

Source: mechanicalbase.com

Source: mechanicalbase.com

Fabrication, structures, properties and applications (deadline: • example • when at least three materials are present, it is called a hybrid composite. Aluminum metal matrix composites have properties that no other monolithic material can match. Metal matrix composites have a continuous metal matrix phase and one or more additional phases such as ceramic reinforcements. Ceramic Matrix Composites And Their Superior Properties.

Source: slideshare.net

Source: slideshare.net

31 august 2022) advances in thermal protection composite materials: The damping capacity and slidingwear behavior of an aluminum; Suitable structural metal matrix (mg, zn, ti) are reinforced with. Metal matrix composites are the class of materials that have received great attention in the past decade owing to their superior specific properties and huge promise of application in various fields like aerospace, automotive, engineering, biomedical, and electronic applications. Metal matrix composites (mmc).

Source: slideshare.net

Source: slideshare.net

The metal matrix composites are deformed into different shapes, and the microstructure is changed to increase the strength of the composites. The paper presents a brief state of the art of advanced ceramics, metal matrix and ceramic matrix composites. Metal matrix composites are the class of materials that have received great attention in the past decade owing to their superior specific properties and huge promise of application in various fields like aerospace, automotive, engineering, biomedical, and electronic applications. When the fibers are increased inside metal matrix, these mechanical properties are also increased. Metal matrix composite by Nishikant Bawiskar.

Source: mechanicalbase.com

Source: mechanicalbase.com

Also these materials are very good thermal and electrical conductors. For instance, welding electrode materials and electrical contact materials consist of a conductive matrix alloy of copper or silver with a tungsten, tungsten carbide, or cadmium oxide second phase, or reinforcement. Each chapter covers different perspectives of micro/nano reinforcement and related applications. International journal of materials science and applications. Fiber Reinforced Metal Matrix Composites Applications And Properties.

The Damping Capacity And Slidingwear Behavior Of An Aluminum;

Each chapter covers different perspectives of micro/nano reinforcement and related applications. In aerospace applications, supremex composites can help you reduce component weight while meeting strength and wear requirements for lower fuel use and carbon emissions. Each chapter covers different perspectives of micro/nano reinforcement and related applications. Numerous researches have been carried out on the developments of metal matrix composites (mmcs) in various applications.

The Applications Of Metal Matrix Composites (Mmcs) Are Being Increasing Day By Day In A Number Of Industries, Especially In Aerospace And Automobile Industries.

However, the main problem related to their processing is that controlling. Experimental testing and fabrication of metal matrix composite for automotive applications. In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement: Due to their superior strength to conventional materials, aluminium matrix composites (amcs) have a broad variety of industrial applications.

Metal Matrix Composites (Mmcs) • A Metal Matrix Composite (Mmc) Is Composite Material With At Least Two Constituent Parts, One Being A Metal.

The applications include ventral fin, fuel. The paper presents a brief state of the art of advanced ceramics, metal matrix and ceramic matrix composites. For instance, welding electrode materials and electrical contact materials consist of a conductive matrix alloy of copper or silver with a tungsten, tungsten carbide, or cadmium oxide second phase, or reinforcement. Ceramic reinforced metal matrix nanocomposites (deadline:

Fabrication, Structures, Properties And Applications (Deadline:

The metal matrix composites are deformed into different shapes, and the microstructure is changed to increase the strength of the composites. This article provides information on the aerostructural, aeropropulsion, and aeronautical subsystem applications of mmcs. Also these materials are very good thermal and electrical conductors. International journal of materials science and applications.