Property data given in this chapter are therefore A composite material is a combination of two materials with different physical and chemical properties.

Free Physical Properties Of Metal Matrix Composites With Creative Ideas, ~carl zweben, “metal matrix composites, ” contractor report for ota, january 1987. A composite material is a combination of two materials with different physical and chemical properties.

(PDF) Mechanical and Material Properties of Metal Matrix Composite From researchgate.net

(PDF) Mechanical and Material Properties of Metal Matrix Composite From researchgate.net

Owing to this merits mmcs are extensively used for various engineering applications. Metal matrix composites (mmcs) possess significantly improved properties including high specific strength; Metal matrix composites are additional resistance to. Jor source of differences in reported properties.

(PDF) Mechanical and Material Properties of Metal Matrix Composite In this chapter the mechanical and physical properties of metal matrix composites are discussed.

A metal matrix composite system is generally designated simply by the metal alloy designation of the matrix and the material type, volume fraction, and form of the ceramic reinforcement. 2 1 as used i n this chapter, the terms1‘al u m inu m, ‘‘magnesium, ” and “titanium” denote alloysof these materials used as matrix metals. Properties of aluminum matrix composites reinforced with zr 48 cu 36 ag 8 al 8 metallic glass particles. Recycling of metals reduces mining and the energy required in processing the metals from the ores, thus reducing environmental impact.

Source: researchgate.net

Source: researchgate.net

To overcome this issue, we proposed to replace the cu and al heat sinks by metal matrix composites (mmcs), more particularly al and cu matrix composites reinforced with carbon. For example, 6061al/30v/o sicp designates a discontinuously reinforced 6061 aluminum alloy with 30 volume percent silicon. The major reason could be both matrix and reinforcements are harder and stronger one hence the properties of the. When combined they produce a material that is specific to a certain work, for instance, to become stronger, lighter, or resistant to electricity and also improve strength and stiffness. (PDF) The Influence of ScF3 Nanoparticles on the Physical and.

Source: web.itu.edu.tr

Source: web.itu.edu.tr

Jor source of differences in reported properties. Metal matrix composites (mmcs) because of their excellent properties such as light weight, higher ductility, higher strength etc. Recycling of metals reduces mining and the energy required in processing the metals from the ores, thus reducing environmental impact. 2 1 as used i n this chapter, the terms1‘al u m inu m, ‘‘magnesium, ” and “titanium” denote alloysof these materials used as matrix metals. Research.

Source: researchgate.net

Source: researchgate.net

Even though, various kinds of mmcs have been developed over the years, among them, aluminum (al) and magnesium (mg) mmcs. The elastic modulus (young’s modulus) of composites is discussed here. Mechanical properties of the specimens shown increase up to 20% reinforcement of sic beyond that no improvement found [28]. Metal matrix composites (mmcs) because of their excellent properties such as light weight, higher ductility, higher strength etc. (PDF) Mechanical and Material Properties of Metal Matrix Composite.

Source: researchgate.net

Source: researchgate.net

To overcome this issue, we proposed to replace the cu and al heat sinks by metal matrix composites (mmcs), more particularly al and cu matrix composites reinforced with carbon. ~carl zweben, “metal matrix composites, ” contractor report for ota, january 1987. This article summarizes the mechanical and thermal properties of discontinuously reinforced aluminum mmcs, laminated metallic composites, and continuously aligned fiber reinforced mmcs. Even though, various kinds of mmcs have been developed over the years, among them, aluminum (al) and magnesium (mg) mmcs. Comparison between (a) pure metals and composite materials Chawla.

Source: slideshare.net

Source: slideshare.net

Properties of aluminum matrix composites reinforced with zr 48 cu 36 ag 8 al 8 metallic glass particles. Jor source of differences in reported properties. Even though, various kinds of mmcs have been developed over the years, among them, aluminum (al) and magnesium (mg) mmcs. To overcome this issue, we proposed to replace the cu and al heat sinks by metal matrix composites (mmcs), more particularly al and cu matrix composites reinforced with carbon. Polymer Matrix Composites (PMC) Manufacturing and application.

Source: slideshare.net

Source: slideshare.net

Department of energy's office of scientific and technical information A metal matrix composite system is generally designated simply by the metal alloy designation of the matrix and the material type, volume fraction, and form of the ceramic reinforcement. Metal matrix composites are additional resistance to. Property data given in this chapter are therefore METAL MATRIX COMPOSITE.

Source: researchgate.net

Source: researchgate.net

For aluminum and magnesium fibrous composites use fibers of boron, carbon, carbides of silicon, and the carbides, nitrides and oxides of refractory. In addition to physical and mechanical properties, the reinforcement also in. Metal matrix composites are additional resistance to. The filler reinforcement into the metallic matrix improves the stiffness, specific strength, wear, creep and fatigue properties compared to the conventional engineering materials. (PDF) Role of SiC ceramic particles on the physical and mechanical.

Source: slideserve.com

Source: slideserve.com

The filler reinforcement into the metallic matrix improves the stiffness, specific strength, wear, creep and fatigue properties compared to the conventional engineering materials. However, these matrices possess good deformability and shape versatility, and their electrical and. Are replacing conventional metallic materials in automobile and aerospace industries. In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement: PPT Subject Composite Materials Science and Engineering Subject code.

Source: slideshare.net

Source: slideshare.net

In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement: Jor source of differences in reported properties. For aluminum and magnesium fibrous composites use fibers of boron, carbon, carbides of silicon, and the carbides, nitrides and oxides of refractory. ~carl zweben, “metal matrix composites, ” contractor report for ota, january 1987. METAL MATRIX COMPOSITE.

When combined they produce a material that is specific to a certain work, for instance, to become stronger, lighter, or resistant to electricity and also improve strength and stiffness. Recycling of metals reduces mining and the energy required in processing the metals from the ores, thus reducing environmental impact. For example, 6061al/30v/o sicp designates a discontinuously reinforced 6061 aluminum alloy with 30 volume percent silicon. Mechanical properties of the specimens shown increase up to 20% reinforcement of sic beyond that no improvement found [28]. Where we could get the sintering for magnesium matrix Composites in.

Source: semanticscholar.org

Source: semanticscholar.org

Aluminum based hybrid metal matrix composite have found extensive applications in field of automobiles. When combined they produce a material that is specific to a certain work, for instance, to become stronger, lighter, or resistant to electricity and also improve strength and stiffness. Tensile properties after mixing of al2o3 and graphite particulates are higher than al6061 alloy [29,31,36]. For aluminum and magnesium fibrous composites use fibers of boron, carbon, carbides of silicon, and the carbides, nitrides and oxides of refractory. Figure 11 from Role of SiC ceramic particles on the physical and.

Source: researchgate.net

Source: researchgate.net

Tensile properties after mixing of al2o3 and graphite particulates are higher than al6061 alloy [29,31,36]. The major reason could be both matrix and reinforcements are harder and stronger one hence the properties of the. Metal matrix composites (mmcs) possess significantly improved properties including high specific strength; Mechanical properties of the specimens shown increase up to 20% reinforcement of sic beyond that no improvement found [28]. (PDF) A Review on Mechanical and Thermal Properties of Aluminum Metal.

Source: aip.scitation.org

Source: aip.scitation.org

Recycling of metals reduces mining and the energy required in processing the metals from the ores, thus reducing environmental impact. In addition to physical and mechanical properties, the reinforcement also in. Property data given in this chapter are therefore ~carl zweben, “metal matrix composites, ” contractor report for ota, january 1987. Matrixfiller interfaces and physical properties of metal matrix.

Source: researchgate.net

Source: researchgate.net

Metal matrix composites are additional resistance to. The major reason could be both matrix and reinforcements are harder and stronger one hence the properties of the. 2 1 as used i n this chapter, the terms1‘al u m inu m, ‘‘magnesium, ” and “titanium” denote alloysof these materials used as matrix metals. Metal matrix composites (mmcs) possess significantly improved properties including high specific strength; (PDF) A REVIEW ON PROCESSING AND TRIBOLOGICAL PROPERTIES OF METAL.

Source: researchgate.net

Source: researchgate.net

Materials, manufacturing and mechanical properties. A 742, materials science and engineering: 2 1 as used i n this chapter, the terms1‘al u m inu m, ‘‘magnesium, ” and “titanium” denote alloysof these materials used as matrix metals. The major reason could be both matrix and reinforcements are harder and stronger one hence the properties of the. SEM image of metal matrix composite sample TiNiCSP2 Download.

Source: semanticscholar.org

Source: semanticscholar.org

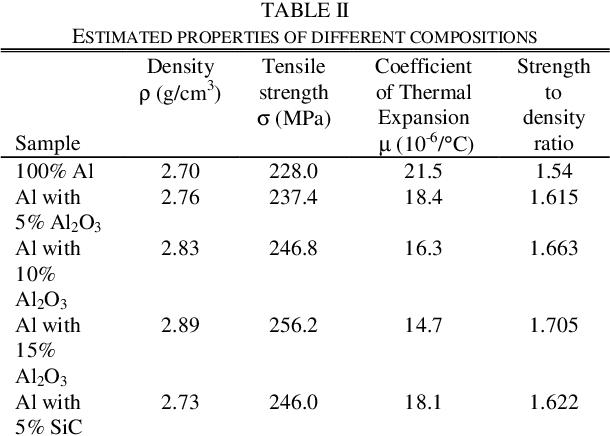

In addition to physical and mechanical properties, the reinforcement also in. However, these matrices possess good deformability and shape versatility, and their electrical and. Materials, manufacturing and mechanical properties. Department of energy's office of scientific and technical information Table II from Physiomechanical Properties of Aluminium Metal Matrix.

Source: aip.scitation.org

Source: aip.scitation.org

A composite material is a combination of two materials with different physical and chemical properties. Property data given in this chapter are therefore Metal matrix composites are additional resistance to. Metal matrix composites (mmcs) possess significantly improved properties including high specific strength; Matrixfiller interfaces and physical properties of metal matrix.

In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement: Metal matrix composites (mmcs) possess excellent properties than that of other materials. For aluminum and magnesium fibrous composites use fibers of boron, carbon, carbides of silicon, and the carbides, nitrides and oxides of refractory. A composite material is a combination of two materials with different physical and chemical properties. Metal Matrix Composites Book Read Online.

Source: researchgate.net

Source: researchgate.net

Jor source of differences in reported properties. Metal matrix composites (mmcs) are composed of at least two physically and chemically distinct phases. In this chapter the mechanical and physical properties of metal matrix composites are discussed. A composite material is a combination of two materials with different physical and chemical properties. Figure1. Types of metal matrix composites, (A) Fiber reinforced (B.

Source: researchgate.net

Source: researchgate.net

In addition to physical and mechanical properties, the reinforcement also in. Property data given in this chapter are therefore A metal matrix composite system is generally designated simply by the metal alloy designation of the matrix and the material type, volume fraction, and form of the ceramic reinforcement. The major reason could be both matrix and reinforcements are harder and stronger one hence the properties of the. Process of Fabrication of Metal Matrix composites Download Scientific.

Source: aip.scitation.org

Source: aip.scitation.org

For aluminum and magnesium fibrous composites use fibers of boron, carbon, carbides of silicon, and the carbides, nitrides and oxides of refractory. Metal matrix composites are additional resistance to. Metal matrix composites (mmcs) because of their excellent properties such as light weight, higher ductility, higher strength etc. Tensile properties after mixing of al2o3 and graphite particulates are higher than al6061 alloy [29,31,36]. Matrixfiller interfaces and physical properties of metal matrix.

Source: aip.scitation.org

Source: aip.scitation.org

Owing to this merits mmcs are extensively used for various engineering applications. However, these matrices possess good deformability and shape versatility, and their electrical and. Mechanical properties of the specimens shown increase up to 20% reinforcement of sic beyond that no improvement found [28]. The filler reinforcement into the metallic matrix improves the stiffness, specific strength, wear, creep and fatigue properties compared to the conventional engineering materials. Matrixfiller interfaces and physical properties of metal matrix.

Source: researchgate.net

Source: researchgate.net

~carl zweben, “metal matrix composites, ” contractor report for ota, january 1987. Metals used as the matrix in metal matrix composites (mmcs), especially aluminum based, are increasingly finding applications in the automotive, aerospace and others. Even though, various kinds of mmcs have been developed over the years, among them, aluminum (al) and magnesium (mg) mmcs. However, these matrices possess good deformability and shape versatility, and their electrical and. (PDF) Investigation of Mechanical Properties of Aluminium Based Metal.

Source: researchgate.net

Source: researchgate.net

Mechanical properties of the specimens shown increase up to 20% reinforcement of sic beyond that no improvement found [28]. Even though, various kinds of mmcs have been developed over the years, among them, aluminum (al) and magnesium (mg) mmcs. This article summarizes the mechanical and thermal properties of discontinuously reinforced aluminum mmcs, laminated metallic composites, and continuously aligned fiber reinforced mmcs. The present work is a study of the effect of reinforcement of different types of. Optical microstructure of Al/SiC P metal matrix composites. (a) Al/0.41.

However, These Matrices Possess Good Deformability And Shape Versatility, And Their Electrical And.

Materials, manufacturing and mechanical properties. Property data given in this chapter are therefore In addition to physical and mechanical properties, the reinforcement also in. The major reason could be both matrix and reinforcements are harder and stronger one hence the properties of the.

Metals Used As The Matrix In Metal Matrix Composites (Mmcs), Especially Aluminum Based, Are Increasingly Finding Applications In The Automotive, Aerospace And Others.

A metal matrix composite (mmc) is compositea metal matrix composite (mmc) is composite material with at least two constituent parts, one being. For aluminum and magnesium fibrous composites use fibers of boron, carbon, carbides of silicon, and the carbides, nitrides and oxides of refractory. Recycling of metals reduces mining and the energy required in processing the metals from the ores, thus reducing environmental impact. Specific modulus, damping capacity and good wear resistance compared to unreinforced alloys.

Metal Matrix Composites (Mmcs) Possess Significantly Improved Properties Including High Specific Strength;

The present work is a study of the effect of reinforcement of different types of. A metal matrix composite system is generally designated simply by the metal alloy designation of the matrix and the material type, volume fraction, and form of the ceramic reinforcement. A composite material is a combination of two materials with different physical and chemical properties. Department of energy's office of scientific and technical information

When Combined They Produce A Material That Is Specific To A Certain Work, For Instance, To Become Stronger, Lighter, Or Resistant To Electricity And Also Improve Strength And Stiffness.

Are replacing conventional metallic materials in automobile and aerospace industries. To overcome this issue, we proposed to replace the cu and al heat sinks by metal matrix composites (mmcs), more particularly al and cu matrix composites reinforced with carbon. Tion on physical and mechanical properties, processing methods, distinctive features,. In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement: