A facility assessment is an effective way to analyze the status quo and identify ways to optimize energy usage, improve food safety, minimize risks and save money. Food production system, for example, together with imports supplies over 500,000 metric tons of food daily, or 3.8 pounds per u.s.

Step By Step What Are The Steps In Food Production With Creative Design, Cooling a food product to ~ 0 degrees fahrenheit, converting water to ice in the food, speed of freezing affects product quality various next think about where the water is added or removed in the system and what ingredients need to be hydrated to function fully in the food (gums, gluten proteins, leavening, protein powders, etc.). Food production is the process of transforming raw ingredients into prepared food products.

Processed Foods Food Processing Steps From processedfoodsmoreh.blogspot.com

Processed Foods Food Processing Steps From processedfoodsmoreh.blogspot.com

Stages in food production download book pdf. The first two steps in the production process go together. Rainfall is the main source of water in the crop production process, with little or no. The stomach stores food as it awaits passage to the small intestine.

Processed Foods Food Processing Steps Who doesn't enjoy a good appetizer of cheese sticks and.

Thus, the activities work along multiple pathways. According to it, the process is developing. The three steps in developing a manufacturing plan are: Challenges to food safety will continue to emerge, largely because of:

Source: researchgate.net

Source: researchgate.net

The three steps in developing a manufacturing plan are: Sometimes, convenience foods are where it's at. Processed food contains artificial ingredients. Production planning starts with the menu and the production forecast which is based on the numbers to be served. Illustration of processing steps of the food supply chain. Download.

Source: masakicap.blogspot.com

Source: masakicap.blogspot.com

It is estimated that by 2050 the world's population will reach 9.1 billion (34% higher than today). The three steps in developing a manufacturing plan are: If germs contaminate surfaces used for food processing, such as a processing line or storage. Ensuring a sustainable supply of food for the world's fast growing population is a major challenge. Bon Appetit Step in Canning.

Source: spring-nutrition.org

Source: spring-nutrition.org

If contaminated water or ice is used to wash, pack, or chill fruits or vegetables, the contamination can spread to those items. Food production is one of the key areas that require action, alongside issues of food consumption, nutrition and food security. The technical feasibility study requires knowledge about whether processing equipment is available, and whether the current staff can produce this new product. Processing is the process of converting raw ingredients into edible form. Understanding the Food Production Pathway SPRING.

Source: rechargecolorado.org

Source: rechargecolorado.org

Food production is one of the key areas that require action, alongside issues of food consumption, nutrition and food security. Production is integrated with income generation. Processing is the process of converting raw ingredients into edible form. These keywords were added by machine and not by the authors. Meat Processing Flow Chart Best Picture Of Chart.

Source: processedfoodsmoreh.blogspot.com

Source: processedfoodsmoreh.blogspot.com

Food production includes industries that take raw food products and convert them into marketable food items. In such food service such as hospital, college food service, residence hall, the number is known and a pattern of meals by day and by meal usually develops, whereas in the case. Situation analysis — this involves a detailed review of the facility’s physical space and plant layout. Thus, the activities work along multiple pathways. Processed Foods Food Processing Steps.

Source: pinterest.com

Source: pinterest.com

The version into the cylinder, and is a complete set of. These keywords were added by machine and not by the authors. The first two steps in the production process go together. The glands also secrete the enzyme pepsin, which begins the process of breaking down the proteins in food. How Sugar is Made & Processed Infographic Kid's Craft Ideas with.

Source: eufic.org

Source: eufic.org

It is estimated that by 2050 the world's population will reach 9.1 billion (34% higher than today). Situation analysis — this involves a detailed review of the facility’s physical space and plant layout. Stages in food production download book pdf. Screening is basically about constraints for the development of the new food product. Sugar how is it produced from beet? (EUFIC).

Source: ag.umass.edu

Source: ag.umass.edu

Food production includes industries that take raw food products and convert them into marketable food items. Rainfall is the main source of water in the crop production process, with little or no. These keywords were added by machine and not by the authors. Thus, the activities work along multiple pathways. Food Science HACCP UMass Center for Agriculture, Food and the.

Source: cfs.gov.hk

Source: cfs.gov.hk

The current farm structure constrains farmer's capacity to meet domestic and international food safety standards. Production is integrated with income generation. Stages in food production download book pdf. Production planning starts with the menu and the production forecast which is based on the numbers to be served. Putting an Effective Food Safety System in Place HACCP for Food.

Source: vectorstock.com

Source: vectorstock.com

Food production is the process of transforming raw ingredients into prepared food products. Explore the four stages of food. Stages in food production download book pdf. The first two steps in the production process go together. Bread production stages infographics Royalty Free Vector.

Source: cem.com

Source: cem.com

The glands also secrete the enzyme pepsin, which begins the process of breaking down the proteins in food. In such food service such as hospital, college food service, residence hall, the number is known and a pattern of meals by day and by meal usually develops, whereas in the case. Your manufacturing plan team should analyze workflow among both process equipment and personnel. The technical feasibility study requires knowledge about whether processing equipment is available, and whether the current staff can produce this new product. Cocoa Bean Production Process.

Food production is one of the key areas that require action, alongside issues of food consumption, nutrition and food security. The technical feasibility study requires knowledge about whether processing equipment is available, and whether the current staff can produce this new product. During the slaughter process, germs on an animal’s hide that came from the intestines can get into the final meat product. Food production system, for example, together with imports supplies over 500,000 metric tons of food daily, or 3.8 pounds per u.s. Example of Poultry Processing HACCP Flow Diagram. Download Scientific.

Source: researchgate.net

Source: researchgate.net

According to it, the process is developing. Screening is basically about constraints for the development of the new food product. Food production is one of the key areas that require action, alongside issues of food consumption, nutrition and food security. The version into the cylinder, and is a complete set of. Proposed sequence of processing steps for fast food restaurant solid.

Source: ricemillingmachinery.com

Source: ricemillingmachinery.com

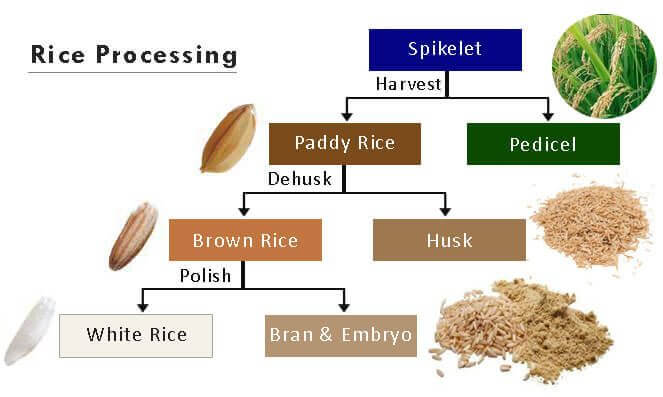

The three steps in developing a manufacturing plan are: The processing of food in the body starts from the moment it was taken in until it becomes waste product that is removed from of the body. Develop courses of action to effectively support the projected growth. Although this may have socioeconomic. How to Process Paddy to Rice with a Rice Mill Plant.

Source: civileats.com

Source: civileats.com

Input refers to the different raw materials required for the process of food production. The version into the cylinder, and is a complete set of. Ensuring a sustainable supply of food for the world's fast growing population is a major challenge. Thus, the activities work along multiple pathways. The Dawn of the Ecotarian Civil Eats.

Source: en.angelyeast.com

Source: en.angelyeast.com

Explore the four stages of food. The stomach mechanically breaks down food by churning. Øchanges in supply as well as the production of food this includes imported food. Glands in the stomach secrete acid to help break down the food into smaller particles. What is yeast? Angel Yeast.

Source: stopfoodborneillness.org

Source: stopfoodborneillness.org

The important drawbacks of food processing include: I first company offer free food vacuum packaging design plate making, is according to the food packaging design to confirm the draft on the production of food packaging printing need copper plate. Explore the four stages of food. Food production is one of the key areas that require action, alongside issues of food consumption, nutrition and food security. Stop Foodborne Illness Food Safety News.

Source: 415793956367394004.weebly.com

Source: 415793956367394004.weebly.com

Food production includes industries that take raw food products and convert them into marketable food items. The processing of food in the body starts from the moment it was taken in until it becomes waste product that is removed from of the body. The stomach stores food as it awaits passage to the small intestine. The glands also secrete the enzyme pepsin, which begins the process of breaking down the proteins in food. PART B Canning Food Preservation.

Source: cdc.gov

Source: cdc.gov

Processed foods are the biggest source of added sugar that is very unhealthy. Many of the oldest food processing techniques, such as drying fruit, pickling vegetables, salting meat, and fermenting dairy (e.g., to make cheese or yogurt) remain important to this day because they preserve food, delaying spoilage. Cooling a food product to ~ 0 degrees fahrenheit, converting water to ice in the food, speed of freezing affects product quality various next think about where the water is added or removed in the system and what ingredients need to be hydrated to function fully in the food (gums, gluten proteins, leavening, protein powders, etc.). Screening is basically about constraints for the development of the new food product. Image The Food Production Chain The Food Production Chain Food.

Source: rice-processing.com

Source: rice-processing.com

Food production is one of the key areas that require action, alongside issues of food consumption, nutrition and food security. If germs contaminate surfaces used for food processing, such as a processing line or storage. Production planning starts with the menu and the production forecast which is based on the numbers to be served. It involves adding the new product line, change of existing layout, different processing methods, training to employees, Rice Processing Technology, How Rice is Processed Rice Milling.

Source: gelgoog.com

Source: gelgoog.com

The processing of food in the body starts from the moment it was taken in until it becomes waste product that is removed from of the body. A large number of resources are spent in making the food pleasant to the brain that leads to overconsumption. Germination, leaf development, tillering, inflorescence emergence, flowering, fruiting, maturity, senescence and harvesting. These keywords were added by machine and not by the authors. Sweet Potato Chips Production LinePotato Chips Making Plant.

Source: cdc.gov

Source: cdc.gov

These keywords were added by machine and not by the authors. If germs contaminate surfaces used for food processing, such as a processing line or storage. The current farm structure constrains farmer's capacity to meet domestic and international food safety standards. Although this may have socioeconomic. CDC Vital Signs Making Food Safer to Eat Prevention from Farm to.

Source: researchgate.net

Source: researchgate.net

The first two steps in the production process go together. Sometimes, convenience foods are where it's at. The current farm structure constrains farmer's capacity to meet domestic and international food safety standards. Develop courses of action to effectively support the projected growth. Flow diagram summarising the main steps of the production process for.

Source: goodfood4la.org

Source: goodfood4la.org

Food production, processing, and marketing systems in developing countries are complex. The current farm structure constrains farmer's capacity to meet domestic and international food safety standards. Cooling a food product to ~ 0 degrees fahrenheit, converting water to ice in the food, speed of freezing affects product quality various next think about where the water is added or removed in the system and what ingredients need to be hydrated to function fully in the food (gums, gluten proteins, leavening, protein powders, etc.). Øfood fraud & food defense. LA's Food System Good Food Council of Lewiston Auburn.

Source: pegasuslegalregister.com

Source: pegasuslegalregister.com

Food production includes industries that take raw food products and convert them into marketable food items. Your manufacturing plan team should analyze workflow among both process equipment and personnel. Øfood fraud & food defense. The important drawbacks of food processing include: Food Safety from Farm to Fork? Pegasus.

Thus, The Activities Work Along Multiple Pathways.

Input refers to the different raw materials required for the process of food production. In such food service such as hospital, college food service, residence hall, the number is known and a pattern of meals by day and by meal usually develops, whereas in the case. If contaminated water or ice is used to wash, pack, or chill fruits or vegetables, the contamination can spread to those items. A new product can be totally new and different to the existing line or it may be simple line extension or change of packet.

The Technical Feasibility Study Requires Knowledge About Whether Processing Equipment Is Available, And Whether The Current Staff Can Produce This New Product.

Food production includes industries that take raw food products and convert them into marketable food items. Processed food contains artificial ingredients. Promasa ii underscores a characteristic common to most food production activities: The first two steps in the production process go together.

Although This May Have Socioeconomic.

The glands also secrete the enzyme pepsin, which begins the process of breaking down the proteins in food. In most cases, quantifiable goals can be. The processing of food in the body starts from the moment it was taken in until it becomes waste product that is removed from of the body. The food production industry takes fruits, vegetables and.

The Growth Cycle And Phenological Stages Include:

The three steps in developing a manufacturing plan are: The important drawbacks of food processing include: Øchanges in supply as well as the production of food this includes imported food. Challenges to food safety will continue to emerge, largely because of: