In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement: Mechanical engineering and materials science independent study.

Step By Step Thermal Properties Of Metal Matrix Composites Ideas 2022, This paper is intended to study mechanical, corrosion and thermal properties of aluminium metal matrix composites with multiwalled carbon nanotubes as reinforcements. Aluminum based hybrid metal matrix composite have found extensive applications in field of automobiles.

MMC (Metal Matrix Composites) is a new material that excels in terms of From jgctrading.com

MMC (Metal Matrix Composites) is a new material that excels in terms of From jgctrading.com

In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement: Mechanically, the addition of the. (sintering) and infiltration technique are used for fabrication copper matrix composites. Evaluation of the effective thermal properties of aluminum metal matrix composites reinforced by ceramic particles.

MMC (Metal Matrix Composites) is a new material that excels in terms of Mechanical engineering and materials science independent study.

The thermal boundary resistance, which occurs at the interface between the metal and the included phase (typically ceramic particles), has a large effect for small particle sizes. ~carl zweben, “metal matrix composites, ” contractor report for ota, january 1987. The composite obtained shows a homogeneous distribution of the reinforcement phase and has a density of 5.99 g/cm3. However, two critical issues have limited their commercialization.

Source: researchgate.net

Source: researchgate.net

Mechanically, the addition of the. The sic particles were mixed with sio2 as an inorganic binder, and cationic starch as a organic binder. This is the widest group of metal matrix composites. Ballambettu chandrasekhara pai, in encyclopedia of materials: (PDF) A Review on Mechanical and Thermal Properties of Aluminum Metal.

Source: slideshare.net

Source: slideshare.net

Processing and properties of metal matrix composites. (sintering) and infiltration technique are used for fabrication copper matrix composites. The aluminum metal matrix composites (ammcs) have been becoming suitable materials for many devices in the application of various fields like. However, two critical issues have limited their commercialization. METAL MATRIX COMPOSITE.

Source: jgctrading.com

Source: jgctrading.com

In addition, these materials have a lower thermal expansion coefficient, which bodes well for applications that require material integrity in extremely high temperatures. For example, an aluminum mmc is often used for applications requiring light weight, high specific mechanical properties while nickel mmcs provide the ability the retain excellent mechanical strength, resist oxidation, and reduce thermal creep at extreme temperatures. The aluminum metal matrix composites (ammcs) have been becoming suitable materials for many devices in the application of various fields like. Evaluation of the effective thermal properties of aluminum metal matrix composites reinforced by ceramic particles. MMC (Metal Matrix Composites) is a new material that excels in terms of.

Source: researchgate.net

Source: researchgate.net

Development of hybrid metal matrix composites has become an important area of research interest in material science. Mechanical engineering and materials science independent study. Valerio oddone *,1 and stephanie reich,1 1 department of physics, free university berlin, arnimallee 14, 14195 berlin, germany keywords thermal conductivity, thermal expansion, metal matrix composite, carbon fibres. Nonferrous alloy based composite is usually consuming the light weight matrix material in which the filler materials disseminated evenly , , , , , , , , ,.the plan of the composite matrix depends up on the several aspects like the purpose of the material, solubility of reinforcement particles ,.the desirable thermal related properties like high absorption and/or. (PDF) Analysis of Mechanical Properties of Aluminium based Metal Matrix.

Source: researchgate.net

Source: researchgate.net

However, two critical issues have limited their commercialization. The thermal conductivity of metal‐matrix composites, which are potential electronic packaging materials, is calculated using effective medium theory and finite‐element techniques. Valerio oddone *,1 and stephanie reich,1 1 department of physics, free university berlin, arnimallee 14, 14195 berlin, germany keywords thermal conductivity, thermal expansion, metal matrix composite, carbon fibres. The following properties are typical for copper matrix composites: (PDF) Physiomechanical properties of aluminium metal matrix composites.

Source: researchgate.net

Source: researchgate.net

The following properties are typical for copper matrix composites: For example, an aluminum mmc is often used for applications requiring light weight, high specific mechanical properties while nickel mmcs provide the ability the retain excellent mechanical strength, resist oxidation, and reduce thermal creep at extreme temperatures. Cte (α) is the second primary property for thermal management. The aluminum metal matrix composites (ammcs) have been becoming suitable materials for many devices in the application of various fields like. (PDF) An overview on mechanical properties of particulate reinforced.

Source: researchgate.net

Source: researchgate.net

This article summarizes the mechanical and thermal properties of discontinuously reinforced aluminum mmcs, laminated metallic composites, and continuously aligned fiber reinforced mmcs. Processing and properties of metal matrix composites. Metallic matrix composites reinforced with carbon nanomaterials continue to attract interest because of their excellent mechanical, thermal, and electrical properties. For example, an aluminum mmc is often used for applications requiring light weight, high specific mechanical properties while nickel mmcs provide the ability the retain excellent mechanical strength, resist oxidation, and reduce thermal creep at extreme temperatures. (PDF) Review of metal matrix composites with high thermal conductivity.

Source: semanticscholar.org

Source: semanticscholar.org

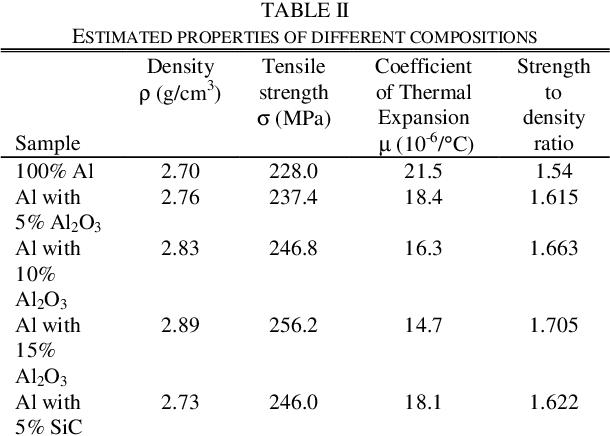

In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement: ~carl zweben, “metal matrix composites, ” contractor report for ota, january 1987. 1 thermal properties of metal matrix composites with planar distribution of carbon fibres. The sic particles were mixed with sio2 as an inorganic binder, and cationic starch as a organic binder. Table II from Physiomechanical Properties of Aluminium Metal Matrix.

Source: researchgate.net

Source: researchgate.net

Processing and properties of metal matrix composites. The composite obtained shows a homogeneous distribution of the reinforcement phase and has a density of 5.99 g/cm3. Metallic matrix composites reinforced with carbon nanomaterials continue to attract interest because of their excellent mechanical, thermal, and electrical properties. For example, an aluminum mmc is often used for applications requiring light weight, high specific mechanical properties while nickel mmcs provide the ability the retain excellent mechanical strength, resist oxidation, and reduce thermal creep at extreme temperatures. Modelling of composite thermal conductivity. Download Scientific Diagram.

Source: slideserve.com

Source: slideserve.com

The composite obtained shows a homogeneous distribution of the reinforcement phase and has a density of 5.99 g/cm3. Processing and properties of metal matrix composites. Ballambettu chandrasekhara pai, in encyclopedia of materials: ~carl zweben, “metal matrix composites, ” contractor report for ota, january 1987. PPT Metal Matrix Composites PowerPoint Presentation ID4344148.

Source: intechopen.com

Source: intechopen.com

Mismatch in the coefficient of thermal expansion and the elastic modulus of the reinforcements and the matrix during cooling and straining [22]. Property data given in this chapter are therefore Aluminum based hybrid metal matrix composite have found extensive applications in field of automobiles. The composite obtained shows a homogeneous distribution of the reinforcement phase and has a density of 5.99 g/cm3. Thermal Conductivity of an inSitu Metal Matrix Composite Cast Iron.

Source: intechopen.com

Source: intechopen.com

(sintering) and infiltration technique are used for fabrication copper matrix composites. Metallic matrix composites reinforced with carbon nanomaterials continue to attract interest because of their excellent mechanical, thermal, and electrical properties. Mmcs are produced by combining two or more materials that exhibit better properties than obtained from individual materials. Processing and properties of metal matrix composites. Thermal Conductivity of an inSitu Metal Matrix Composite Cast Iron.

Source: pdfslide.net

Source: pdfslide.net

Cte (α) is the second primary property for thermal management. (sintering) and infiltration technique are used for fabrication copper matrix composites. Nonferrous alloy based composite is usually consuming the light weight matrix material in which the filler materials disseminated evenly , , , , , , , , ,.the plan of the composite matrix depends up on the several aspects like the purpose of the material, solubility of reinforcement particles ,.the desirable thermal related properties like high absorption and/or. Jor source of differences in reported properties. Fabrication and Analysis of Mechanical Properties of Metal Matrix Nano.

Aluminum based hybrid metal matrix composite have found extensive applications in field of automobiles. Tests are conducted to evaluate for hardness,. The sic particles were mixed with sio2 as an inorganic binder, and cationic starch as a organic binder. 1 thermal properties of metal matrix composites with planar distribution of carbon fibres. Analysis of Mechanical Properties of Aluminium Based Metal Matrix.

Source: researchgate.net

Source: researchgate.net

The thermal conductivity of metal‐matrix composites, which are potential electronic packaging materials, is calculated using effective medium theory and finite‐element techniques. Ballambettu chandrasekhara pai, in encyclopedia of materials: Cte (α) is the second primary property for thermal management. The following properties are typical for copper matrix composites: (PDF) Investigations for Mechanical Properties of Metal Matrix.

Source: mdpi.com

Source: mdpi.com

2 1 as used i n this chapter, the terms1‘al u m inu m, ‘‘magnesium, ” and “titanium” denote alloysof these materials used as matrix metals. Nonferrous alloy based composite is usually consuming the light weight matrix material in which the filler materials disseminated evenly , , , , , , , , ,.the plan of the composite matrix depends up on the several aspects like the purpose of the material, solubility of reinforcement particles ,.the desirable thermal related properties like high absorption and/or. Metallic matrix composites reinforced with carbon nanomaterials continue to attract interest because of their excellent mechanical, thermal, and electrical properties. Valerio oddone *,1 and stephanie reich,1 1 department of physics, free university berlin, arnimallee 14, 14195 berlin, germany keywords thermal conductivity, thermal expansion, metal matrix composite, carbon fibres. Materials Free FullText Thermal Conductivity of Diamond Composites.

Source: jgctrading.com

Source: jgctrading.com

1 thermal properties of metal matrix composites with planar distribution of carbon fibres. This is the widest group of metal matrix composites. Uniform distribution of carbon nanomaterials in metallic matrices is difficult, and the interfaces between the. (sintering) and infiltration technique are used for fabrication copper matrix composites. MMC (Metal Matrix Composites) is a new material that excels in terms of.

Source: researchgate.net

Source: researchgate.net

The thermal conductivity of metal‐matrix composites, which are potential electronic packaging materials, is calculated using effective medium theory and finite‐element techniques. Jor source of differences in reported properties. The sic particles were mixed with sio2 as an inorganic binder, and cationic starch as a organic binder. The aluminum metal matrix composites (ammcs) have been becoming suitable materials for many devices in the application of various fields like. Thermal conductivity of studied composites Download Scientific Diagram.

Source: researchgate.net

Source: researchgate.net

The thermal conductivity of metal‐matrix composites, which are potential electronic packaging materials, is calculated using effective medium theory and finite‐element techniques. Tests are conducted to evaluate for hardness,. Mmcs are produced by combining two or more materials that exhibit better properties than obtained from individual materials. Metallic matrix composites reinforced with carbon nanomaterials continue to attract interest because of their excellent mechanical, thermal, and electrical properties. (PDF) Material characterisation and mechanical properties of Al2O3Al.

Source: researchgate.net

Source: researchgate.net

The composite obtained shows a homogeneous distribution of the reinforcement phase and has a density of 5.99 g/cm3. The thermal boundary resistance, which occurs at the interface between the metal and the included phase (typically ceramic particles), has a large effect for small particle sizes. This is the widest group of metal matrix composites. ~carl zweben, “metal matrix composites, ” contractor report for ota, january 1987. (PDF) Fabrication process and thermal properties of SiCp/Al metal.

Source: researchgate.net

Source: researchgate.net

The thermal boundary resistance, which occurs at the interface between the metal and the included phase (typically ceramic particles), has a large effect for small particle sizes. Nonferrous alloy based composite is usually consuming the light weight matrix material in which the filler materials disseminated evenly , , , , , , , , ,.the plan of the composite matrix depends up on the several aspects like the purpose of the material, solubility of reinforcement particles ,.the desirable thermal related properties like high absorption and/or. Mmcs are produced by combining two or more materials that exhibit better properties than obtained from individual materials. Tests are conducted to evaluate for hardness,. (PDF) Investigation of Mechanical Properties of Aluminium Based Metal.

Source: researchgate.net

Source: researchgate.net

Metallic matrix composites reinforced with carbon nanomaterials continue to attract interest because of their excellent mechanical, thermal, and electrical properties. In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement: The following properties are typical for copper matrix composites: Ballambettu chandrasekhara pai, in encyclopedia of materials: Mechanical properties of the composite material Download Scientific.

Source: jgctrading.com

Source: jgctrading.com

Uniform distribution of carbon nanomaterials in metallic matrices is difficult, and the interfaces between the. In addition, these materials have a lower thermal expansion coefficient, which bodes well for applications that require material integrity in extremely high temperatures. Jor source of differences in reported properties. This is the widest group of metal matrix composites. MMC (Metal Matrix Composites) is a new material that excels in terms of.

Source: mdpi.com

Source: mdpi.com

This paper is intended to study mechanical, corrosion and thermal properties of aluminium metal matrix composites with multiwalled carbon nanotubes as reinforcements. Property data given in this chapter are therefore The composite obtained shows a homogeneous distribution of the reinforcement phase and has a density of 5.99 g/cm3. This article summarizes the mechanical and thermal properties of discontinuously reinforced aluminum mmcs, laminated metallic composites, and continuously aligned fiber reinforced mmcs. Polymers Free FullText Effective Assembly of NanoCeramic.

Source: what-when-how.com

Source: what-when-how.com

In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement: Evaluation of the effective thermal properties of aluminum metal matrix composites reinforced by ceramic particles. Property data given in this chapter are therefore The following properties are typical for copper matrix composites: Metalmatrix composites.

This Article Summarizes The Mechanical And Thermal Properties Of Discontinuously Reinforced Aluminum Mmcs, Laminated Metallic Composites, And Continuously Aligned Fiber Reinforced Mmcs.

In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement: The following properties are typical for copper matrix composites: 2 1 as used i n this chapter, the terms1‘al u m inu m, ‘‘magnesium, ” and “titanium” denote alloysof these materials used as matrix metals. Aluminum based hybrid metal matrix composite have found extensive applications in field of automobiles.

Jor Source Of Differences In Reported Properties.

The composite obtained shows a homogeneous distribution of the reinforcement phase and has a density of 5.99 g/cm3. Evaluation of the effective thermal properties of aluminum metal matrix composites reinforced by ceramic particles. For example, an aluminum mmc is often used for applications requiring light weight, high specific mechanical properties while nickel mmcs provide the ability the retain excellent mechanical strength, resist oxidation, and reduce thermal creep at extreme temperatures. Metallic matrix composites reinforced with carbon nanomaterials continue to attract interest because of their excellent mechanical, thermal, and electrical properties.

The Aluminum Metal Matrix Composites (Ammcs) Have Been Becoming Suitable Materials For Many Devices In The Application Of Various Fields Like.

In contrast, reinforcement is mostly ceramics in particulate, continuous or discontinuous fibres and whiskers [1]. Tests are conducted to evaluate for hardness,. In addition, these materials have a lower thermal expansion coefficient, which bodes well for applications that require material integrity in extremely high temperatures. Ballambettu chandrasekhara pai, in encyclopedia of materials:

Valerio Oddone *,1 And Stephanie Reich,1 1 Department Of Physics, Free University Berlin, Arnimallee 14, 14195 Berlin, Germany Keywords Thermal Conductivity, Thermal Expansion, Metal Matrix Composite, Carbon Fibres.

Property data given in this chapter are therefore Mechanically, the addition of the. Metal matrix composites (mmcs) are used for structural, electrical, thermal, tribological and environmental applications. (sintering) and infiltration technique are used for fabrication copper matrix composites.